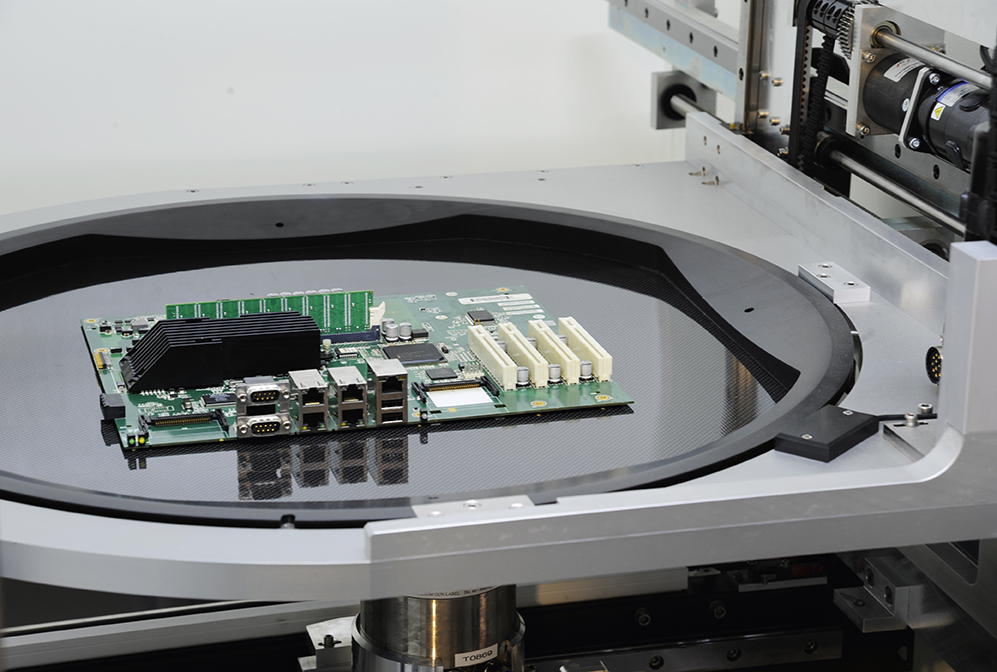

Our diagnosis and repair process

We have developed a diagnostic and repair process that ensures optimal restoration of your industrial robot parts. This process includes several key stages, from initial analysis to final quality testing, to ensure that every repaired part meets our high standards.

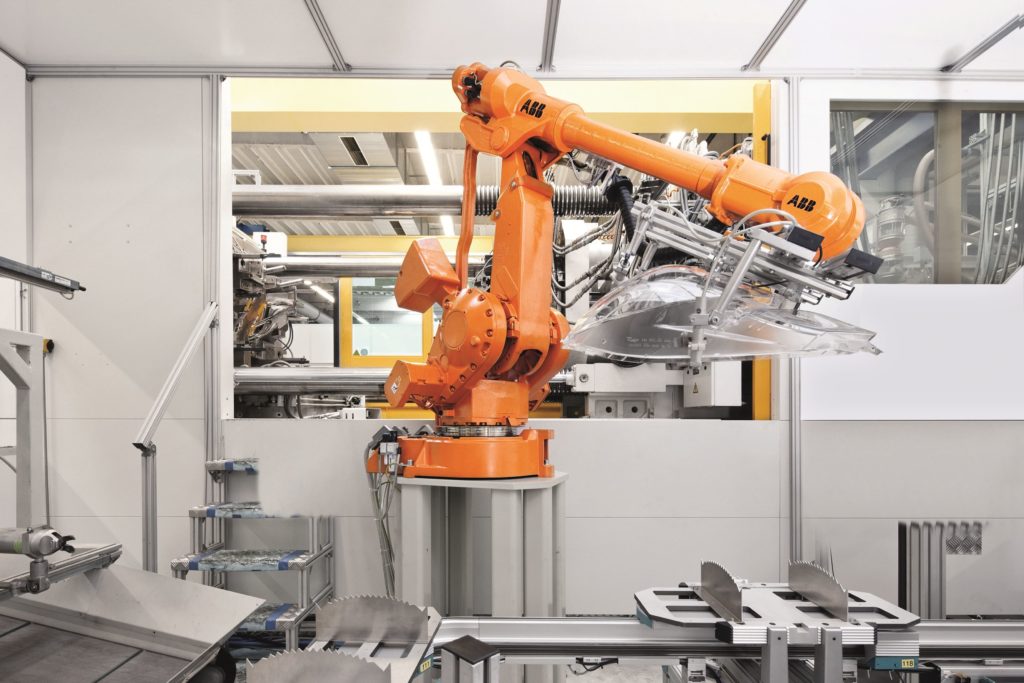

An advanced diagnosis

Our first step is an advanced diagnosis of the faulty part.

To achieve this, we use state-of-the-art equipment, such as a BGA machine for microprocessor-based ball welding, and X-ray equipment for precise internal visualization.

These technologies enable us to accurately identify defects and areas requiring intervention.

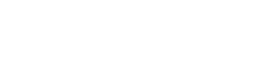

Repair steps

Once the diagnosis has been made, we proceed with the actual repair.

This phase can include replacement of damaged components, complex welds, and other necessary mechanical or electronic repairs.

Our team of technicians restores each part to its ideal working condition, using genuine spare parts and proven techniques.

Testing and quality assurance

After repair, each part undergoes a series of rigorous tests to ensure that it works to original specifications.

These tests simulate real-life conditions to verify the reliability and durability of the repairs carried out.

Our diagnostic and repair process is designed to offer a complete and reliable solution, enabling you to maximize the life and efficiency of your industrial equipment.