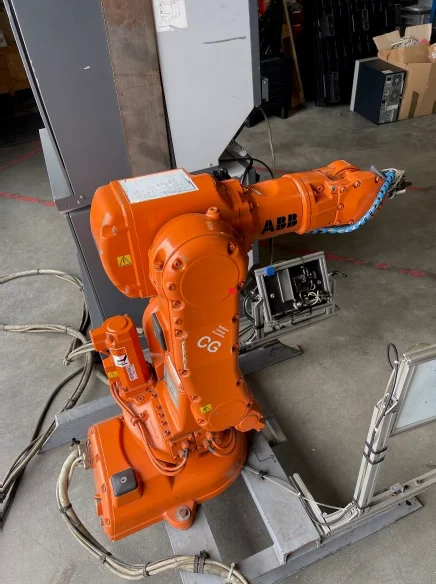

Predictive Maintenance: A Revolution for the Robotic Industry

Industry 4.0 is radically transforming the way companies use technology to improve efficiency and cut costs. One of the most promising innovations in this field is predictive maintenance, a practice that is gaining in popularity, particularly in the industrial robotics sector. BKTRONIC, a leader in industrial robot repair and maintenance, integrates this technology to offer its customers cutting-edge services.

What is Predictive Maintenance?

Predictive maintenance is an innovative approach that uses real-time data collection and analysis to anticipate potential breakdowns and failures before they occur.

This method relies on several advanced technologies, including IoT (Internet of Things) sensors, artificial intelligence (AI), and data analysis, to continuously monitor the condition of industrial machinery and equipment.

In short, predictive maintenance represents a major advance in industrial equipment management, enabling companies to maximize efficiency, reduce costs and prevent breakdowns before they occur. At BKTRONIC, we integrate this technology into our services to offer our customers innovative and efficient solutions for managing their industrial robots.

Benefits of Predictive Maintenance

Cost reduction :

- By anticipating breakdowns before they happen, companies can avoid costly, unplanned repairs. According to BKTRONIC, this method reduces maintenance costs by 10 to 40%.

Increased productivity :

- Unplanned production stoppages can be extremely costly. Predictive maintenance ensures maximum robot availability by minimizing downtime.

Resource optimization :

- By targeting maintenance interventions only when necessary, companies can use their resources more efficiently. This includes reducing spare parts inventory and optimizing technician time.

Extending Equipment Life :

- By keeping robots in optimum condition, their service life is extended, which represents significant savings over the long term.

Case studies and feedback

Several BKTRONIC customers have already benefited from the implementation of predictive maintenance. For example, a major automotive manufacturing company reduced downtime by 30% using this approach.

BKTRONIC's technicians were able to anticipate and correct malfunctions before they affected production, enabling a consistently high production rate to be maintained.

Conclusion

Predictive maintenance represents a paradigm shift for the robotics industry. By enabling companies to move from reactive to proactive maintenance, BKTRONIC helps its customers reduce costs, improve productivity and extend the life of their equipment.

The integration of this technology into BKTRONIC's services demonstrates its commitment to remaining at the forefront of innovation to offer optimal solutions to its customers.